Know What You Need

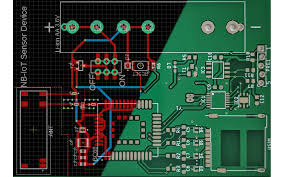

The primary and must step that enables you to rank high in success for ordering online with PCB is having a good insight on the project in hand. It includes the size of board, number of layers, type of material, thicknesses and some other technical specifications (copper weight, surface finish, etc.) Proper specifications are important as they will determine how well the PCB will work and how and where you can use it within your project.

You may need PCB with a particular type of high-frequency material like Rogers or Teflon, if you are working with high-frequency application. The PCB thickness can vary anywhere between 0.4 mm to 3.2 mm in accordance to the structural requirements of your board. Having these details means that the PCB manufacturer can meet the specific requirements for your need.

Choose the Right Manufacturer

Choose Your PCB Manufacture Wisely Try finding manufactirers who propose a solid price-to-quality-to-lead time ration. The verification process of a reputable manufacturer (as well as the enlisted material, methods of production, all the new technologies). We suggest you to go through their customer reviews and even consider taking a sample PCB produced by them before placing an order in big quantity.

The ISO 9001 certification level of a manufacturer is the easiest and good measurement of the reliability of a manufacturer — this basically means that they belong to a group of very few manufacturers who play by the rules of high-quality management. Moreover, if the manufacturers are able to offer real-time technical support and DFM (Design for Manufacturability) checks, the error rate can be reduced drastically.

Take Advantage of Web Based Design and Ordering Tools

Use PCB manufacturings on at lowers outliners design builder for simplification of design and ordering. The vast majority of top-tier manufacturers have free PCB design tools, instant quote capabilities, and real-time order tracking functionalities. These solutions specialize in allowing you to see your PCB before fabrication, rapidly generate a cost quote, and overall maintain full visibility of the process from initial order through to physical delivery of your PCB.

This kind of a tool, such as this online quote system can also give you an immediate estimation of the cost by entering your PCB specifications that will help in budget management. This is generally coupled with the ability to request order changes (eg. different production times or shipping methods)

Ensure that The File Format and Design Guidelines are Respected

Make sure your PCB files are formatted properly Gerber RS-274X is the recognized standard format accepted by the vast majority of manufacturers. Make sure to submit high-quality designs without errors to prevent any production-related accidents. It is crucial to stick to the design guidelines given by the manufacturer for manufacturability and functionality of your PCB.

Non-adherence to these guidelines may lead to delays or mistakes in the production. For example, a too narrow traces can result in broken traces, not enough spacing between the trace can results to short circuits.

Test-Plan with Quality Gates

Every time you order PCBs from online PCB manufacturers, make sure to ask them about their testing and quality assurance methods, And also plan for it. This step is very important to guarantee that we will provide you with boards that work as per optimized requirements so as not to get back with any faults back. In some of the more advanced factories, you can also run AOI (Automated Optical Inspection), flying probe tests, and functional tests.

This will increase the overall cost, but testing is invaluable in reducing the risk of failure in your end product. According to sources, advanced test methods can increase PCB reliability by up to 40%.

In order to order pcb online successfully, you must carefully plan your order and be familiar with the machining process. To avoid such a mess and to attain the perfect outcomes from PCB projects, it is good learning practice to streamline your specification, choose a reliable manufacturer, utilize online tools properly, follow the correct design file format and prepare for quality assurance.